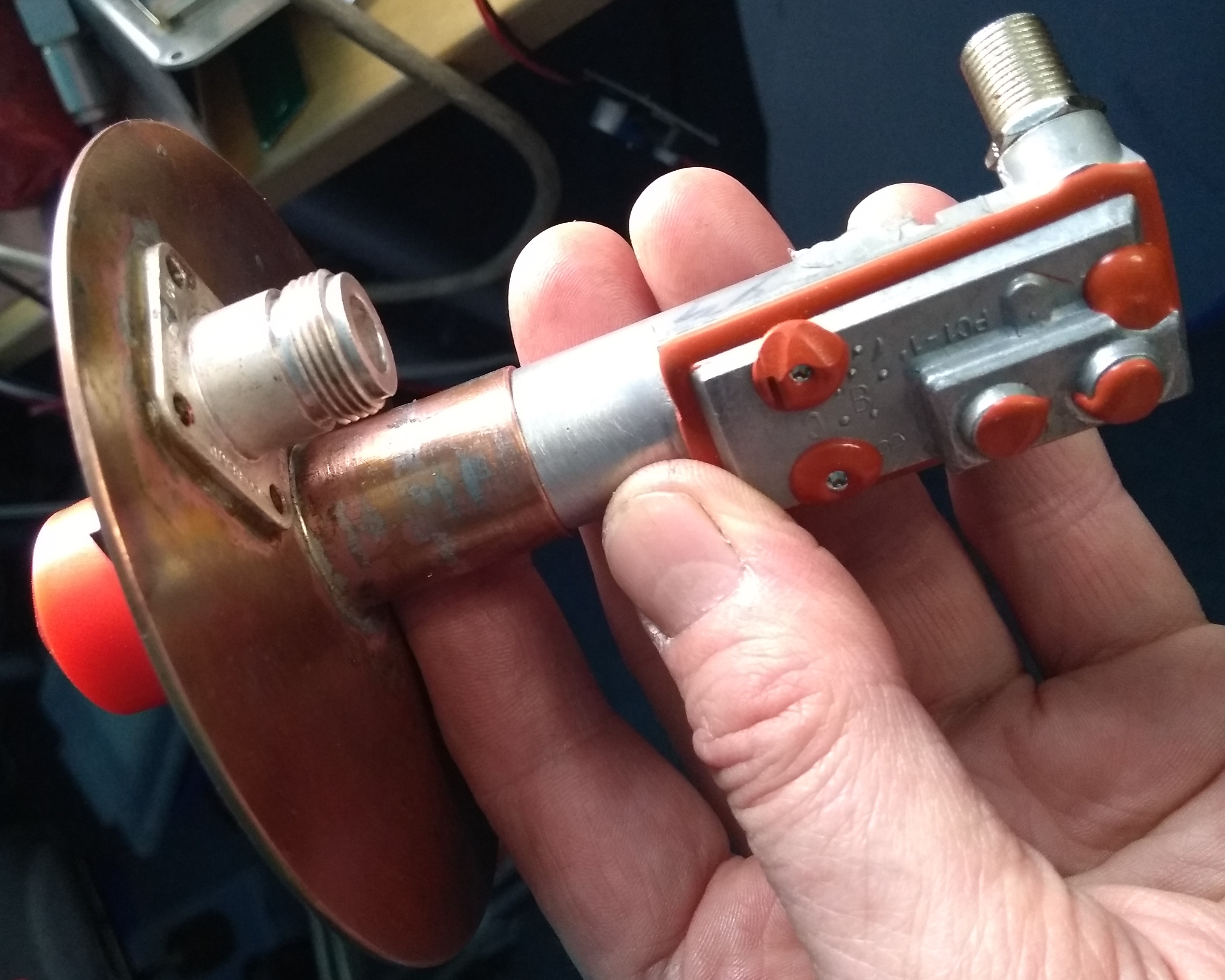

Got it all together and soldered it all in one lot with a gas torch and care! Rather than using a bulky compression fitting I put the completed feed in the lathe and took about 0.5mm out of the LNB end of the copper pipe. Then, using a strip of emery cloth, I reduced the external diameter of my LNB. It is now a nice snug 'twist-fit' in the end of the copper. To seat the Rocket internals at the right height I have left the protruding copper at 16mm in front of the patch. Will this be an issue I wonder? - without it being that length, the inner bit will move around at will?? I will design a simple step-up ring for mounting in my LNB holder, pop it on the 3-D printer to make and then trial-fit. Not got a long run from shack to dish so various options on the actual cable I'll use and where I put the amp.

All good fun

Gareth

- 2019-04-13 18.08.42.jpg (1.39 MiB) Viewed 9012 times

PS the stray solder is from where I assembled it earlier, with something that wasn't a N-type and with the patch the wrong way round! Doh!!